Coffee Fermentation: 8 things you probably didn’t know

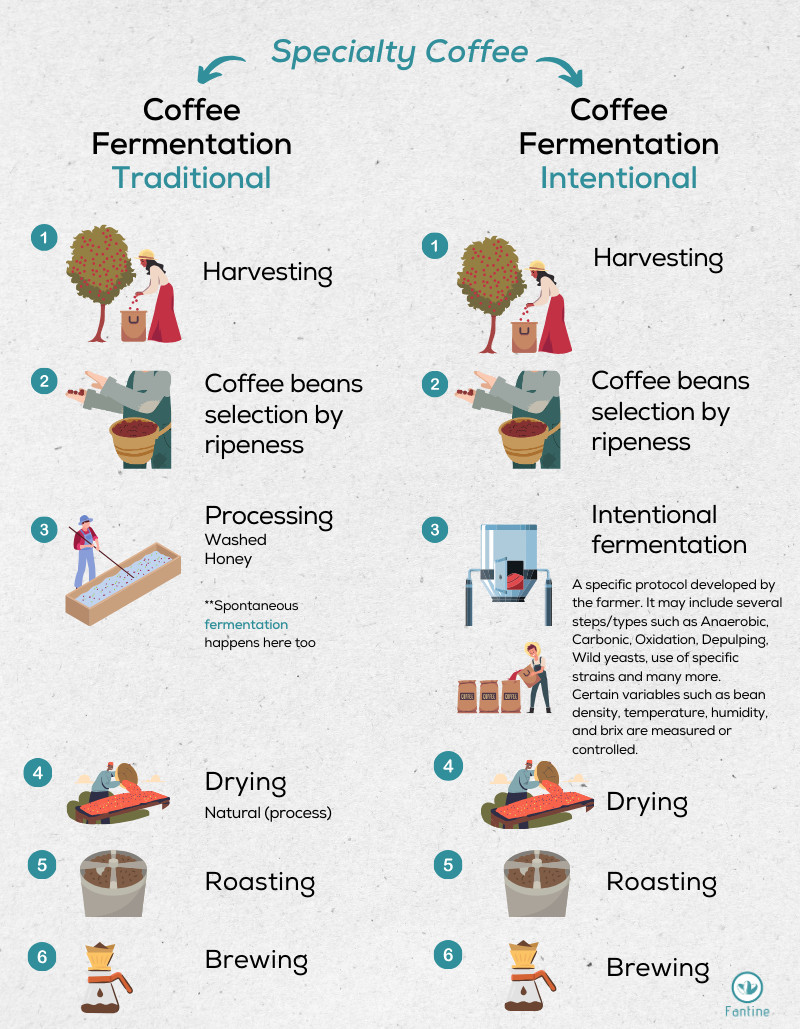

Coffee fermentation is a complex biochemical process that largely influences how you perceive the coffee in the cup. Indeed, the quality of the beverage depends to a large extent on how the cherries are fermented.

In the highly competitive coffee market, many producers are focusing on making specialty coffees. This is because specialty coffees can command higher prices than regular coffee and help producers avoid the ups and downs of the market.

By producing unique, memorable and complex coffees, producers can differentiate themselves and attract customers willing to pay more for high-quality coffee

What influences coffee quality?

The taste of coffee depends on many things, like the type of coffee cultivar, the weather and soil where it’s grown, how the farmers take care of it, and how ripe the coffee cherries are when they’re picked. But the way the coffee is processed is especially important. One key part of processing is fermenting the coffee cherries, which helps bring out the flavors and aromas we love in our coffee.

If the quality of the harvested cherries is poor, no fermentation process, no matter how good it is, will improve the coffee cup quality. Likewise, an incorrect processing and fermentation process will result in a flawed cup, even if the coffee cherries used to carry out that specific process were of outstanding quality.

In other words, both the quality of the coffee cherries and the processing and fermentation methods are crucial in determining the final taste of the coffee. If either of these factors is flawed, the coffee will not meet its full potential.

Keep reading because here are 8 things you might not know about coffee fermentation.

1. Coffee fermentation is not the same as processing.

Fermentation is just only one step in the entire process of processing coffee and it is one of the most important ones.

Coffee processing starts with the pulping (despulpado) of the ripe cherries and ends with the drying of the parchment coffee (pergamino). With the help of a pulping machine, the hulls of the cherries are separated from the kernels.

The beans are coated with mucilage consisting of water, reducing sugars, and pectin. The coffee cherries, freshly separated from the husk and covered by the mucilage, are placed in tanks where the fermentation process takes place.

In the case of washed coffee, once the fermentation process has been completed, the cherries are rinsed with clean water and the beans are dried. In the case of Honey coffee, the cherries are taken to the drying station without being washed beforehand, so they will carry some mucilage with them.

This mucilage will continue to ferment during the drying process, giving the beans a sweeter, fruitier taste than the washed ones.

However, if the fermentation process is carried out incorrectly, incompletely, or for longer than required, it will result in a poor-quality coffee beverage.

2. Coffee fermentation is a biochemical process.

Coffee fermentation is a process involving microorganisms, especially yeasts of the genus Saccharomyces, Torulopsis, Candida and Rhodotorula, as well as lactic acid bacteria Lactobacillus and Streptococcus. (Puerta Q. & Rios A., 2011)

These microorganisms digest the external coffee mucilage by excreting enzymes that are capable of breaking down pectin and complex sugars into simple sugars that the microorganisms can digest.

Other by-products of the process include alcohols, organic acids and carbon dioxide gas, as well as aromatic substances such as aldehydes, ketones and esters that have very characteristic odours.

Although in most food fermentation processes the yeast responsible is always the same, Saccharomyces cerevisiae, in each specific production site there are other indigenous micro-organisms naturally present in coffee cherries, such as other Saccharomyces strains and lactic acid bacteria that are responsible for the unique taste and quality characteristics of each origin.

3. Fermentation products are different depending on the duration of the process.

Fermentation is considered to be an anaerobic process. This means that it occurs in the absence of oxygen. However, yeasts are optional anaerobic micro-organisms that can live both in the presence or absence of oxygen. Thus, what happens during fermentation is a succession of different processes.

At the beginning, coffee fermentation starts under aerobic conditions. Yeasts begin to degrade the simplest sugars while consuming oxygen and releasing carbon dioxide. As CO2 is produced, the substrate becomes more acidic and once all the oxygen in the substrate has been used up, the anaerobic fermentation begins.

During the anaerobic fermentation stage, the more complex sugars such as pectin are hydrolysed, partly by the enzymatic action of the microbial group and to a large extent by the acidity of the substrate. It is the anaerobic fermentation process that yields alcohol as a by-product.

At the end, the compounds produced during the fermentation process will have given to the coffee beans those flavours and aromas that will later be evident in the cup. However, if the coffee fermentation process is not stopped in time, the alcohols will continue to degrade and a subsequent by-product, acetic acid, will be produced in greater quantities, which in turn will give the coffee an unpleasant vinegar taste.

4. Temperature affects the fermentation time

Since fermentation is a biochemical process that is caused by living organisms, temperature directly influences it. As a general rule, the higher the temperature, the higher the biological activity, because micro-organisms reproduce faster at higher temperatures. As the microbial population increases, it will break down the organic substrates in a shorter time.

Conversely, at lower temperatures, microbial colonies reproduce more slowly and fermentation processes will take longer. For this reason, ambient temperature is a key factor to take into account in the coffee fermentation process. Freshly pulped coffee remains in the fermentation tanks between 14 and 24 hours depending on the ambient temperature. Therefore, the warmer the climate, the faster the fermentation process.

During this time, bacteria and yeasts ferment the mucilage, which eventually turns into a fluid honey that can be easily separated from the kernel. In the case of washed coffees, the fermentation process is completed at this stage and the coffee processing moves on to the next steps of washing and drying.

Normally, coffee farmers determine the duration of the coffee fermentation process empirically. They usually do it either by taking a handful of cherries which are then rubbed together to produce a sound similar to rubbing small stones against each other, or by sticking a piece of wood into the coffee mass in the tank. In the latter case, if a hole remains when the wood is removed and the fermented coffee mass does not crumble, the coffee is ready to be washed.

5. Over-fermented coffee: myth or reality?

When fermentation takes place at ambient temperatures of approximately 15°C and for up to 48 hours, the beans acquire complex and delicate flavours. At higher ambient temperatures between 18-26°C, if the fermentation lasts longer than 36 hours, defects arise and unpleasant woody, rancid and sour flavours may be produced.

This happens because alcohols start to degrade, and higher amounts of acetic acid are produced which in turn give a vinegar taste to the cup. For this reason, up until a few years ago it was common to hear that extending the duration of fermentation beyond 24 hours after the washing point had been reached, would result in cups with unpleasant flavours.

Today this is still true, however, coffee farmers are working to develop controlled fermentation protocols whose times extend to 50 hours and more, depending on the process and the ambient temperature of each location. This results in sweeter cups, tartaric acidity and very special and exotic flavours and aroma attributes.

6. There are many different ways of performing the coffee fermentation process.

Open tank, with solid mass, static and discontinuous.

This is the traditional way of carrying out coffee fermentation at coffee farms. It is carried out in open tanks where the solid mass of coffee beans with mucilage (café en baba) is accumulated, which remains static (without agitation).

In this case, the fermentation time depends mainly on the ambient temperature and the process is discontinuous, because it starts and ends with each batch of coffee that is harvested and processed. If carried out correctly, complex cup profiles with fruity, citrus and chocolate notes are obtained.

Submerged mass.

This consists of fermenting the coffee in open tanks, with the coffee mass submerged in water, which is stirred at the beginning and at the end of the process. In this case, an amount of water equals to roughly 30% of the total volume of the fermenting mass is added into the fermentation tank. The water dilutes the sugar concentration and regulates the temperature so that the fermentation times can be lengthened.

Compared to solid fermentation, submerged fermentation has the advantage that fermentation occurs more uniformly across the entire coffee mass and a more alkaline pH is maintained during the process. Submerged fermentation of coffee results in very smooth cups with caramel notes.

With or without prior cherry fermentation.

In traditional coffee processing, cherries are pulped the same day they are harvested. Until recently, it was considered a mistake in the processing of washed coffees to leave the coffee cherries unpulped for more than 12 hours. This is mainly due to the fact that once a cherry is harvested, a natural fermentation process starts.

When the coffee is pulped one or two days after being harvested, the parchment that covers the coffee kernel takes on a reddish colour, which is considered a defect when selling the dried coffee. This can lead, in many cases, to vinegary flavours in the cup.

However, it has been proven that when pre-fermentation of cherries is carried out in a controlled manner, interesting attributes can be achieved in the cup. The duration of this pre-fermentation usually ranges from 24 to 48 hours, depending on the climate and the thickness of the layer of cherries remaining at rest.

In general, this should be no thicker than 30 centimetres to avoid overheating and overfermenting in the lower layers. Many producers are now experimenting and each one is developing their own way of doing it. You may come across pre-fermentation protocols (i.e. still in cherry) with longer times and in thicker layers. Even inside closed tanks. These processes, combined with the fermentation processes themselves, allow for sweeter and fruitier cups with malic and tartaric acidity.

In closed tanks, with mixing and in a continuous manner.

This is the way coffee is fermented in large processing plants. The pulped coffee is placed into closed fermentation tanks where it remains for a certain period of time and is removed before adding the next batch of cherries. In this way, the process never stops. As we saw in the previous sections, the fermentation process involves lactic acid bacteria and yeasts that are optional anaerobic micro-organisms and require oxygen to operate in aerobic conditions.

Therefore, in a closed system, two things are necessary: 1) an oxygen supply system to keep the micro-organisms alive and 2) a constant stirring system, which is needed to homogenise the coffee masses added into the tanks. In an open fermentation system, instead, the microbial populations vary over time. Initially, the yeasts act. As oxygen decreases and chemical reactions occur in the substrate, such as PH variations and changes in the concentration of the different types of sugars, the yeast population decreases and the population of lactic acid bacteria increases.

That’s why in closed continuous fermentation systems, it is necessary to supply oxygen and replenish the microbial populations by inoculation, in order to keep them always at the right levels. Only in this way, the fermentation process can be carried out permanently. Continuous fermentation produces coffees with notes of hazelnut, vanilla and flowers. Earthy flavours can sometime occur too.

7. Controlled coffee fermentation as a way to obtain differentiated cup profiles.

Protocols of controlled coffee fermentation enable to produce specialty coffees with notable variations in their flavours and intensity. They also make it possible to emphasize the presence and concentration of volatile and aromatic compounds responsible for the aroma.

Today, coffee farmers and coffee entrepreneurs are constantly working on the development of rigorous coffee fermentation protocols that can be replicated and performed over and over again in order obtain differentiated and consistent cups over time.

Controlled fermentation and inoculation.

As we have already said, yeasts of the genus Saccharomyces and lactic acid bacteria are responsible for the fermentation process. Nevertheless, in each coffee field there are specific indigenous microbiota, determined by the particular environmental conditions of the location, the variety of coffee grown, the flora associated with the crop and the coffee processing methods. Such microbial complexes are specific to each cultivation and production site and influence the coffee fermentation process.

Brazilian researchers working on the Nucoffee Artisans project, after 20 years of research, have succeeded in identifying, isolating, purifying and reproducing these indigenous microbial complexes specific to each region where coffee is grown. The objective it to use them as a starting inoculum during controlled fermentation processes in closed tanks.

In this way, it would become possible to control the presence of unwanted microorganisms during the process and be able to obtain cups of coffee with new flavours and desirable sensory attributes that depend upon the composition of the inoculum used.

As an example, an intense strawberry flavour was one of the most unusual and outstanding flavours obtained with this method. Another advantage is that the process could be replicated over time, giving those characteristic cups year after year despite seasonal variations.

8. Controlled coffee fermentation and signature coffees.

Producers and baristas started to experiment with new and innovative processes such as carbonic maceration. Carbonic maceration is a process that until now has only been applied in wine production.

In this process, fermentation takes place in an anaerobic environment saturated with CO2, where the lactic acid bacteria rather than the yeasts, are responsible for the process.

This results in coffees with interesting vinous cup profiles when the fermentation is done properly. However if improperly processed, carbon maceration may lead to unpleasant flavours of vinegar caused by the creation of acetic acid.

Others, more adventurous, have even tried to add different types of fruit to the coffee mass during the fermentation process. This is intended to increase the level of sugars during the coffee fermentation process and to develop additional flavour and aroma attributes.

These processes require a great deal of knowledge and expertise. It is paramount to analyse and identify the microbial complex that acts on fruit substrates other than coffee. Additionally, the volume, degree of ripeness and brix degrees of the added fruit must also be determined.

Clearly, one must also control the duration of the fermentation and its temperature, as well as the changes in the acidity of the substrate during the entire process. Only in this way, the protocols can be replicated to obtain consistent cups with special attributes.

Most orthodox coffee professionals consider this practice as an artificial way of flavouring coffee and not as a process where the natural potential of flavours and aromas of the coffee bean is developed. Others discourage this approach, saying that it does not permit obtaining elegant profiles and instead simply ruins the good work done on the field.

However since there are products for all tastes in the market, this type of coffee is aimed at consumers who enjoy different experiences and more exotic flavours. This could be an interesting alternative for roasters and baristas who want to conquer new markets.

Tell us if you already knew all these aspects about coffee fermentation or if you have had any particular experience you want to share. We invite you to subscribe to our blog so that you can be informed about new articles and updates on the exciting world of coffee.

Sign up to our newsletter receive monthly articles and updates on the exciting world of coffee, as well as offers from producers.